Most net companies aren’t us. In fact, we’re one a kind. I have come to believe that we don’t have any “competitors”…yes there are other companies that

supply nets for catamarans & overwater nets, but none of them come close to being on our level of quality & service. We are the only tensioned net supplier

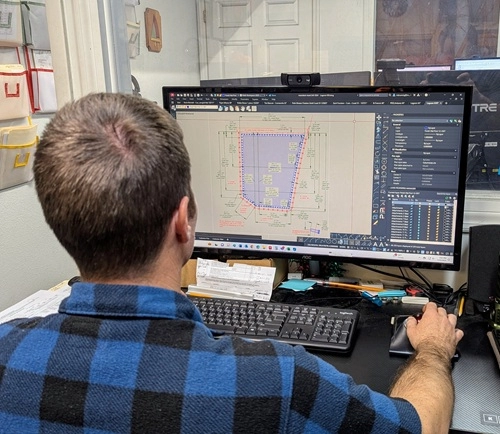

that has a dedicated Net Engineer team to support your purchase & installation through every step of the process. Our Net Engineers will act as your assistant

buyer to ensure you get the right product for your boat’s needs, walk you through ensuring a perfect fit design, and support you through any installation

questions you might have (although with our terrific support content & documentation for installation you won’t have many questions). Where else will you

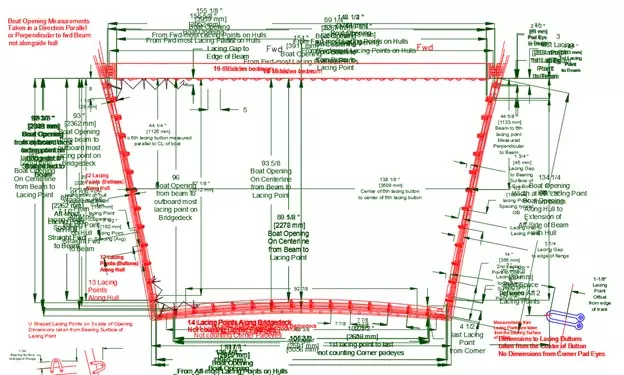

find a CAD drawing completed for Every. Single. Net. We. Make? (Hint, not on this planet).

This should probably be table stakes for a netting company, but it’s not and it’s a large part of what makes us different. In a very good way.

Figure 1: If you know Mach Schnell, you know they do things right. There's a reason our Silver Dyneema nets are on this boat.

Figure 1: If you know Mach Schnell, you know they do things right. There's a reason our Silver Dyneema nets are on this boat.

The Dirty Secret About "Standard" Boat Nets

Even boats of the same make and model have different dimensions. I know that seems surprising, but after 38 years of doing this I can assure you this

is all too true.

Take the Lagoon 380. Roughly 1,000 of these were built

over two decades, making it one of the most popular cruising cats ever produced. You'd think a "Lagoon 380 net" would be... a Lagoon 380 net. We have

over 20 different drawings on file for this one model. Twenty. Covering 4 major variants. Some have lacing buttons, some have U-straps.

The attachment point spacing varies. Bridgedeck curvature changed between production years. We've seen 3+ inches of difference between boats with the same

model name on the transom.

Lagoon 380 drawing overlay showing multiple variants - demonstrates the 20+ drawings and 4 major variants.

Lagoon 380 drawing overlay showing multiple variants - demonstrates the 20+ drawings and 4 major variants.

So what do other net companies do about this? Most of them build to an average and cross their fingers. If it doesn't quite fit, well, they know many

customers will accept it and consider it good enough. Some don't even acknowledge the variation exists, they just sell you "a Lagoon 380 net" and call it a day.

That’s how many people end up with nets with ridiculous lacing gaps like the below image:

Figure 2: Bad design. We do it better. A lot better.

Figure 2: Bad design. We do it better. A lot better.

We took a different approach. We built a system to actually handle it and ensure that we do it right for our customers.

How We Handle Your Order

When you contact us, your order goes one of three ways depending on your boat:

If your boat model is consistent like the

Lagoon 450, which has been remarkably standardized throughout its production), our engineers recommend materials, colors, lacing configurations, you

pick what you want, and we build from patterns we've verified over years of production.

If your model has known variations(like that Lagoon 380, or the

Leopard 46, or dozens of others), the process starts with a photo. Send us a picture of your boat opening, and we can identify which variant you have

and pull the right drawing from our database. We send that drawing to you, you check a few measurements against your actual boat, and if anything's

off, even by a little, we adjust the design before we cut anything.

One customer in North Queensland, Australia, described what this looked like for him:

"Richard Leng emailed a very detailed drawing of the tramp dimensions for the L380 for us to check before construction. There were slight differences & they

then altered & made it to measure. Very comforting considering we are in North Queensland, Oz... a very long way away from them."

That's a guy on the other side of the planet getting the same precision as someone who drops by our shop in Florida. That's the whole point of having a

system perfected over the past 38+ years.

If you have a custom boat or something we haven't seen before, our engineers work from scratch. You send rough dimensions and photos, we

develop a drawing. For boats with compound curves or weird geometries, we walk you through our Sunrise Triangulation Method,

a technique we've refined over nearly four decades for accurately remotely capturing shapes that don't fit into neat rectangles.

Either way, you get a drawing for approval before manufacturing starts. And we guarantee the fit.

38 Years of Drawings (And Why That Matters)

We've been at this since 1987. Every boat we've ever built a net for had a dedicated design drawing. Since about 1995 we’ve done them all in Autocad.

Every time a manufacturer quietly changed something mid-production, we noted it. Every quirk that only shows up after you've done hundreds of the same

model we’ve documented.

The database now has over 400 boat models and thousands of individual drawings. It's not sitting in a filing cabinet

gathering dust; our engineers use it daily.

A recent example: We recently saw that the Neel 47 trimaran modified

one edge of their boat design mid-production. Not obvious from photos. Not obvious from basic dimension checks. A customer's net didn't fit. We took

ownership by redesigning the net, rushing it through production at our cost, and updating the database to check for this inconsistency on that model so

future Neel 47 customers don't hit the same issue.

That's how the system gets better. Every boat teaches us something.

What the Engineering Team Actually Does

I realize "our engineers help you" is a bit vague, so let’s talk a few specific examples.

We manage multi-variant drawings. Not one drawing per boat model—multiple variants tracking production changes, regional differences,

manufacturer updates. When you order, they match you to the right one. Not a generic pattern.

We optimize lacing patterns. Every net ships with a CAD drawing showing exactly how to lace it, specific to your net's geometry. The

physics matter, and we take them into account. Tension transfer depends on the lacing approach angle. Wrong pattern = improper tension = shorter net life

/ less stable net. (The white paper goes deep on this if you're curious.)

We verify before we cut. We don't just trust your measurements and hope for the best. We create a CAD drawing and send it to you for

verification before manufacturing. This is why we can guarantee fit, we catch problems before they become problems.

A Cruisers Forum member summed it up: "They took our order, sent the drawing through for confirmation, and three weeks later we had a new tramp. Three

years on it still looks great with no signs of wear."

LINK

We handle remote dimensioning worldwide. No templates to ship, no site visits needed. We've been doing this remotely for 38 years. It's

routine for us even when it feels complicated to you. As one customer put it: "It was great to be able to order this remotely without needing to have someone

come out to measure or taking our boat somewhere to have it done."

Working With Boat Builders

We work extensively with aftermarket nets, but we also provide nets for many of the quality focused new boat manufacturers. Many of our new boat manufacturing

partners take us up on something we offer all of them: talk to us early in your design process. (And I wish all of them did!)

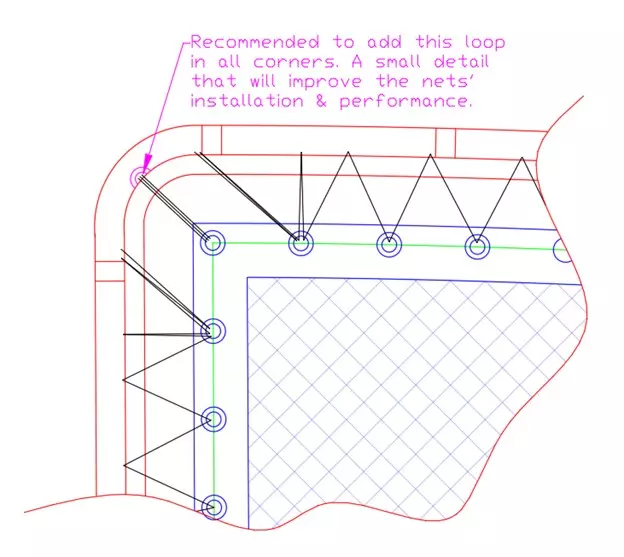

Trampoline attachment systems tend to be an afterthought in new boat designs. Naval architects are (understandably) focused on hull performance and interior

layout. Where the lacing points go? That's often a "figure it out later" item. Problem is, bad lacing point design affects net tensioning, longevity, and

usability for the life of the boat.

Common mistake we see:

No fixed corner lacing points. These make installation easier and corner tensioning dramatically better. Without them, you're fighting for

proper tension at the corners forever. Most builders leave them out because nobody told them to include them.

Lacing points placed too far from corners. Creates tensioning dead zones.

Spacing in the 5.5" to 7" range. This is awkward lacing point spacing…it’s too wide for optimal alternating

lacing patterns, too tight for double lacing. We can work with it, but the net won't perform as well as it would have

with slightly different spacing.

When the crew of SV Delos (700,000+ YouTube subscribers)

(LINK to Youtube channel) started building their Explorer 53 expedition cat, they worked with us on net design including allowing us to help design their

attachment point layout. Their plans were initially lacking some fixed corner lacing points which to the designer were a non-obvious detail if you don't make

nets for a living. Because they came to us early, adding it was a simple tweak during standard production instead of expensive rework later. Their nets will

tension correctly and as a result will be easier to install, look more attractive, and perform a little bit better. You’ll be able to see these for yourself

soon!

Figure 3: Our Net Engineers care about the details.

Figure 3: Our Net Engineers care about the details.

We Train Engineers to Be Your Assistant Buyer

This is something we’re really proud of. We've trained our engineers to act like they're buying the net for you, not selling it to you.

If you're ordering nets for a boat you're selling in two years, we can help with more budget oriented yet still high quality nets (although in most cases

it’s still worth getting the exact right net for your boat as our nets on board will help enhance the boat’s resale value). If you sail protected coastal waters,

they may steer you towards considering appropriate material options that may be more comfort oriented than blue-water sailing focused. As an example, many of our

customers call in wanting Dyneema nets because Dyneema is cool (it is cool), however for many of our cruising customers Dyneema isn’t the best options and we’ll

actually recommend a less expensive net that is a better fit for their particular needs (typically 3/8” Offshore with its improved comfort & durability).

Why? Because we want to be our customers’ netting solution partner for the next 25 years, not just for this sale. This means we have to live for the long-term

good of our customers.

This Is Also About Safety

I've written about catastrophic net failure before, that "unzippering" thing where one strand

breaks, overloads the adjacent strands, and suddenly you've got a person-sized hole opening up faster than you can react. If you haven't read that piece, you

should. It's a real risk most owners don't think about.

Figure 4: There's a reason this hole is person-sized. Someone went through it (luckily they weren't hurt in this case).

Figure 4: There's a reason this hole is person-sized. Someone went through it (luckily they weren't hurt in this case).

Our engineering addresses this through proper grommet spacing, reinforced borders, and materials that maintain strength for 12+ years in tropical sun. The

drawing verification process ensures attachment points align correctly with our border design, preventing the stress concentrations that accelerate failure.

Behind the scenes, our net engineers have focused on perfecting the net materials, manufacturing processes, and coatings to make our nets the World’s Most

Durable Nets. How? It took over 20 years to develop the current methods & materials we use. For these 20 years we’d inspect every net that failed and find out

exactly what the weak point was – then we’d fix it. After doing that over and over and over we removed all the weak points leaving us with a time-tested net design

that allows us to offer the World’s Best Tensioned Netting Warranty.

When you step on one of our nets, you're stepping on something engineered to be safe and attractive for a decade or more, not a cheap solution to fill in that

open space in the front of your boat for a few years.

What Ships With Every Net

Custom installation drawing. Not a generic instruction sheet, but a CAD drawing for your specific net with lacing patterns optimized for your

geometry. See our installation page for more on the process.

Labeled components. Everything marked and identified. One customer's reaction: "WOW! Just WOW!... Everything marked, lacing lines tagged. Even

the detail of a tag line to run the cable for the Bow Nets! I am super impressed! Damn, if everyone paid that kind of attention to detail. They don't, you do."

Support during and after installation. Phone, email, video call. Business hours Eastern time—we're not 24/7, but when we're here, we're

available.

Installation videos. On our YouTube channel and installation page.

Commercial Clients Get It

Private owners appreciate what we do. But when commercial operations, companies whose business depends on their nets, keep coming back, that says something.

Chukka Caribbean Adventures (one of the Caribbean's largest adventure tourism companies):

"Chukka Caribbean Adventures is pleased to acknowledge the outstanding work of the Sunrise Yacht team in manufacturing and delivering our over-water cabana nets.

With future projects on the horizon, they will undoubtedly continue to be our preferred choice. Caleb deserves special recognition for his exceptional performance."

Nassau Yacht Haven:

"Kudos to you and your company for how the netting was packed and labelled. It really made it easy to sort all the components out for installation. We did get a

practiced hand off one of our port based catamarans to come do the actual installation as he has had much practice at this. He was also impressed with your

product and how it arrived."

When your business runs on getting things right, you don't take chances on suppliers.

Sunrise Yacht Products engineer reviewing CAD drawing for custom catamaran net

Sunrise Yacht Products engineer reviewing CAD drawing for custom catamaran net

All Nets Are Not Created Equal

Our "competitors" sell catamaran nets, often at lower prices. However, they don't offer:

- Engineers who verify your boat's dimensions before manufacturing

- A database of 400+ models with variant-specific drawings built over 38 years

- Drawing checks that catch problems before they become ill-fitting nets

- A fit guarantee backed by engineering (not just a return policy)

- Custom installation drawings for every order

- People trained to recommend what you need, not what makes them the most money

Is it worth 2-3x what you'd pay elsewhere? When our nets last 12+ years instead of 3-5, fit right the first time, come with engineering support throughout

the process, and carry the World’s Best Tensioned Netting Warranty you will find that in the great majority of cases we

offer the better lifetime value.

You're buying 38 years of accumulated knowledge, a team that wants to get your specific boat right, and the confidence that comes from knowing someone

actually engineered this thing. And what I want to emphasize here in particular is that you will get by far the world’s best tensioned netting support from

our in-house net engineers!