How to Choose a Large Multihull Net

-By Sunrise Yacht Products-

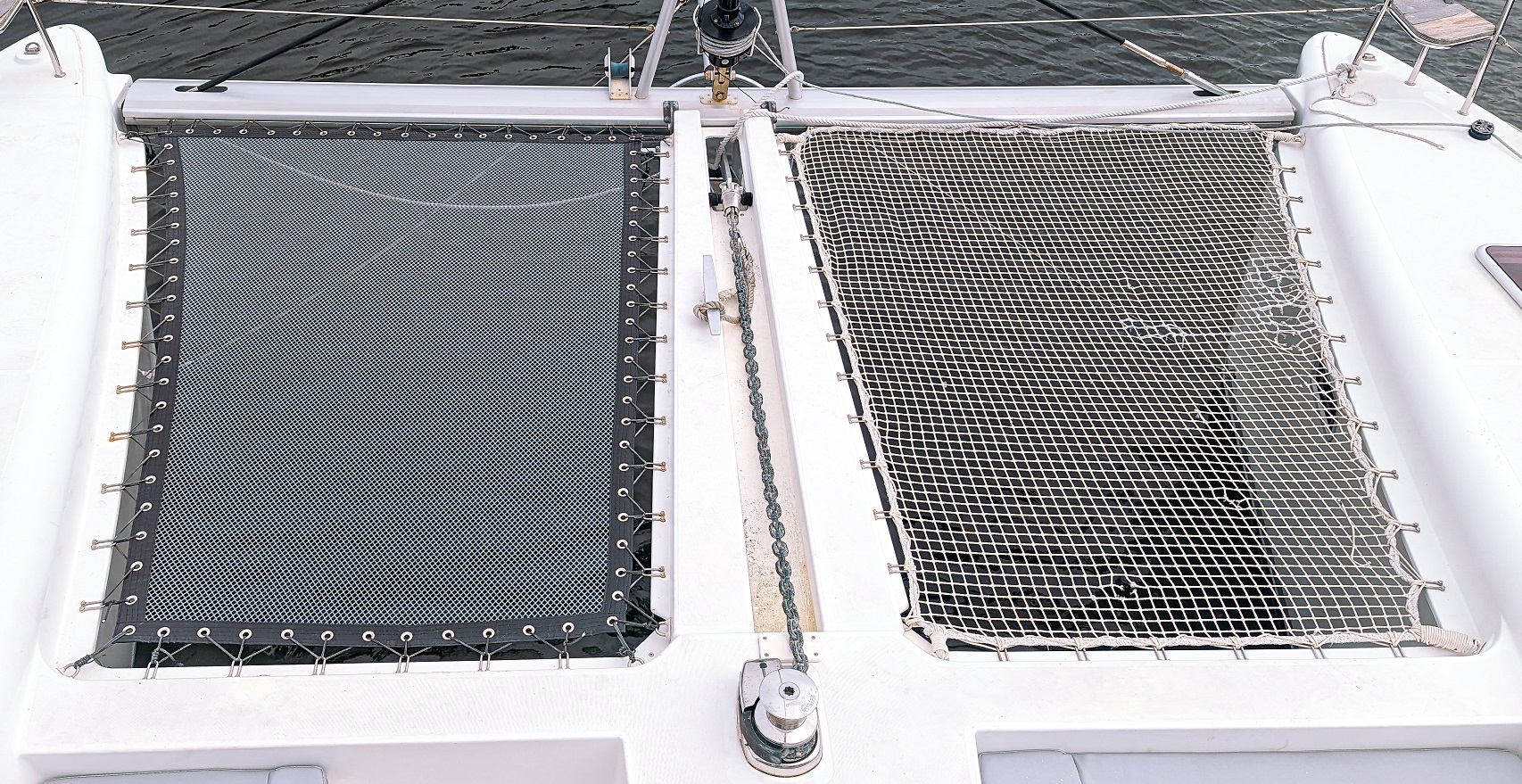

Figure 1: Which of these nets would you prefer to have on your boat?

Figure 1: Which of these nets would you prefer to have on your boat?

Choosing a net can be complicated without a guide, the purpose of this guide is to make it as easy as you want it to be. We have drawings for hundreds of production

model catamarans & trimarans and you can find them by make / model starting with the buttons below or going here.

When you get to your make though, there are going to be a LOT of options, read further down this page to better understanding of what options will be a good fit for you.

At the top is the executive summary version, and you can read on further for additional details. For for a full engineering level white paper with all the details jump straight to

this page. Durable trampoline nets are a critical safety item for your craft & being that they compose between 25 & 35% of your functional living

space we believe they should also highly comfortable & attractive. Most catamaran manufacturers save a little cost by providing their boats with cheap netting that only lasts a

few years in the tropics while still being really uncomfortable – we are here so you can address that with a quality upgrade for your net that will provide many more years of improved service.

Use the buttons below for your catamaran or trimaran manufacturer.

The Executive Summary Version:

If you do not want all the details & want to skip straight to the answer section for which of our nets would be the best option for your 35-60’ catamaran here are the answers:

If budget is a major driver, but you still want the safety & durability of one of our nets, the 1-1/4” Ultra-Pro,

DyneemaCore Rope border is a great solution…although not as comfortable on bare feet as the 3/8” Offshore below, it does have 85% of the durability and with all of our

colors it looks great! Expected functional life 11-13 years. See example pictures here.

The majority of you are going to be best with 3/8” Offshore for its excellent blend of comfort & durability.

It is the gold standard upgrade to OEM nets and is better in every aspect. These are the best material for around 70% of you all and they’re the default

best option for cruising catamarans with an expected functional life 12-15 years. You can see example pictures here.

For those that want the ultimate in net stability underfoot as well as durability our expedition grade 1” webbing nets are strongly worth considering…just keep in

mind that these can have a longer lead time due to the amount of craft work required to construct them. Expected functional life 15-18 years.

You can find example picture here.

If you’re wanting the highest possible performance, the 1” Dyneema nets are a great way to save some pounds & get a very stable net with it’s low weight & stretch.

Expected life 9-11 years for Silver Dyneema, 11-13 years for black dyneema. You can find example pictures for silver

& black.

For those sailing in more protected conditions or with smaller nets, our Square Hole Mesh nets are a good option. For some of the Caribbean chartered boats

that will not be Bluewater sailed they can be a great fit…they will often work on Bluewater boats (all Leopards have this style material), but we do replace

these periodically for customers that sailed through rough conditions that damaged the net & the attachment points but they do have a very good level of

durability & comfort for their cost. Example pictures can be seen here.

If budget is the ONLY driver, then we are likely not the best option for you. You can find nets that are less expensive than our cheapest options with other suppliers.

If you need the least expensive possible net to get you through the next 1-2 years these could be your best option. If you have plenty of time and may not want a fully

polished look you may also consider constructing your own nets, but before you do I would highly recommend checking out our white paper writeup on net design

here to help you out in the process.

The Reasoning Behind The Executive Summary

The Executive Summary above gave you the answers, read on for the reasoning behind the answers we just gave. If you want really get into the design philosophy,

check out our tensioned netting design white paper here for more engineering design details & considerations if you want to go

down the rabbit hole.

There are 5 main parameters to consider when selecting a net:

Safety: The net must be open enough for the boat size & design. We have some general rules of thumb in this chart.

The recommended openness for a given size of net can vary a little in either direction depending on how the boat will be used…a boat sailing in controlled conditions

in the Caribbean can often do with a lower openness net, while boats that are going to be used for circumnavigation will want to strongly consider this chart.

The safety of the net is also strongly tied into durability which is the 2nd parameter to consider.

Durability: The nets’ durability & mode of failure are both a safety & headache reduction consideration. Most nets supplied from the factory are 30mm nets

(such as the one that can be seen on the right in the picture at the top of this page) with a standard life in the tropics of 2-5 years. They are typically weakly

protected from UV at best and can have catastrophic failure modes…particularly if left to sit in the sun for some time & then used. This can result in tears such

as the one in the picture below which can be life threatening at sea. Due to the level of UV protection we give to our nets, none of the nets recommended in this

guide have EVER experienced catastrophic/unzippering failures and they offer much improved durability (11-16 years expected life depending on material). Durability

strongly plays into value consideration as a cheap net will look ratty & need to be replaced 3+ times over the life one high quality net.

Figure 2: What a catastrophic style failure looks like

Figure 2: What a catastrophic style failure looks like

Budget/Value: While similar, these are not interchangeable. A high quality net that lasts 3 times as long as a cheaper net requires 2 fewer purchases &

installations and is often the better value. That said, sometimes budgets are limited and are a higher driver than overall net value. In this case, the best value

is usually going to be 1-1/4” Ultra-Pro, DyneemaCore rope border. These are typically around the same cost from us as replacement nets from the boat manufacturer while offering

2-1/2 to 3 times the durability & the ability to choose any of our colors.

Comfort: The net forms a substantial portion of your living space on the boat – typically 25-35% of your livable space and it should add to the comfort of the boat.

Imagine getting your dream home but putting a dirt floor in the living room! Comfort is generally inversely related to the openness of the net so to optimize comfort you

should generally select the smallest openness that is good for your boat design. For the great majority of 35’ – 60’ catamarans this is optimized by our 3/8” Offshore

or 1” Webbing nets. These nets will be MUCH more comfortable than original 30mm nets under bare feet or when relaxing on the nets enjoying your time on the water.

Aesthetics: How the net looks & feels is important when it’s such a large part of your living space. Choice of materials & of colors can greatly impact the

aesthetics of the space. Color plays a particularly important role in several aspects. One is in maintenance, white is a difficult color to maintain particularly

in the presence of Sahara dust which is a reason our non-white colors are so popular. Also, darker colors are much easier to see through, take a look at how it is

easier to see through the Black nets compared to the

White nets. Your eyes will treat the extra light reflected from the white net the same

as the camera does in these pictures meaning that you won’t see the darker details (such as anchor line) behind the net. One question we get asked a lot is if black

nets are ok or if they get too hot…the short answer is they don’t get too hot due to their high surface area & low thermal mass.

Figure 3: Example rope border net with heavy scalloping with resulting failure points due to high point stress loading on a slightly weakened net.

Figure 3: Example rope border net with heavy scalloping with resulting failure points due to high point stress loading on a slightly weakened net.

I could keep going (and have done so in the White Paper), but I’ll just address one more thing here and that is the

difference between rope borders & grommet borders. Rope borders have some deficiencies which is why we developed the reinforced grommet border, but they have their

place. Rope border nets are going to exhibit much more scalloping due to their lack of planar reinforcement. These dips mean that all the load on this net is being

taken up by these strands immediately adjacent to the lacing points…in essence ¼ to 1/3rd of the net strands are taking all the load and if the net fails it is most

likely to be adjacent to the lacing points (see example picture above). This results in much faster failure particularly on poorly UV protected nets…they lose a ton

of strength from UV exposure then fail at these high stress points. As a result, we only offer Rope Border nets with materials that are over-engineered for strength

& with high UV protection. We developed & perfected the reinforced grommet border was developed between about 1990 & 2010. With each iteration we found what failed

first…this took longer & longer each time…and then we fixed it. The result is today’s reinforced grommet border design which combines multiple layers & types of

reinforcement to add both toughness & stiffness to the net edge. This border offers incredible durability and because it has less deflection it makes for a better

tensioned net. Today’s nets with our reinforced grommet border will typically last 13+ years.

We hope this has been helpful for you, and please don’t hesitate to reach out and contact us if you have any questions!

Regards,

Matt, Mike, & Caleb